In modern hydraulic systems, the return oil filter serves as a vital purification device, safeguarding the stable operation of the system with its superior performance. By utilizing high-precision filter media, it effectively removes solid particles, metal shavings, and dust from hydraulic oil, ensuring fluid cleanliness and thereby reducing wear on hydraulic components and extending equipment lifespan. Its low-pressure drop design maintains efficient fluid flow even under high-flow conditions, significantly reducing energy loss and enhancing overall system efficiency.

The return oil filter also boasts excellent high-pressure resistance and corrosion resistance, enabling stable operation in complex industrial environments and withstanding harsh conditions such as high temperatures, high pressures, and chemical corrosion. Its compact structure and flexible installation options allow it to be easily integrated into various hydraulic systems without occupying excessive space. Additionally, equipped with a filter element blockage indicator and a bypass valve, it not only alerts users to replace the filter element in time but also automatically opens the bypass when the filter element is clogged, ensuring normal system operation and further enhancing equipment reliability and maintenance convenience.

Thanks to its high efficiency, energy-saving, and durability, the return oil filter is widely applied in fields such as construction machinery, metallurgy, petrochemicals, and mechanical processing, becoming a core component to ensure the efficient and stable operation of hydraulic systems.

Features

Contamination Indicator

Visual or electrical contamination indicator can be installed on the filter to observe the contamination of element.

Diffuser(Optional)

The diffuser can diffuse the direction of return oil under large flow, thus making it not easy to produce bubbles and reducing the occurrence of turbulent flow.

By-pass Function(Optional)

By-pass valve will crack to protect the normal operation of element and the system when pressure drop reaches to the set value.

Self-sealing Device

When changing the element or maintaining the system, open the filter cover, self-sealing device will automatically shut down so as to cut off the oil-way and prevent it from flowing out.

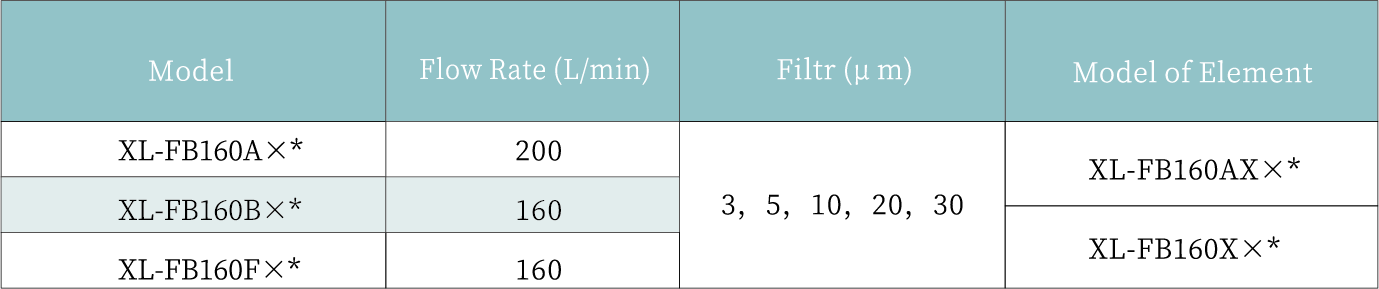

Specifications

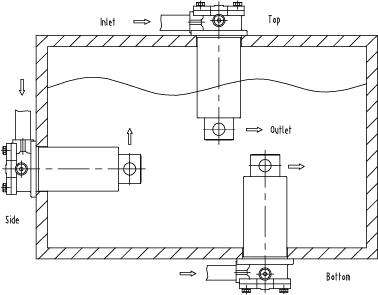

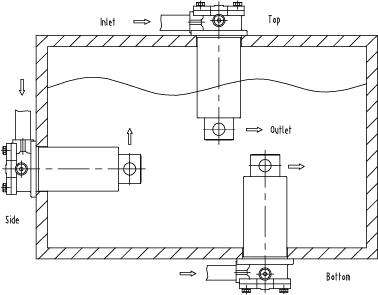

Type of Construction: Tank Top Mounted,Tank Side Mounted

Max Pressure: 1.6MPa

Flow Range: 160~200L/min

Connection: Flange

Operating Temp: -40℃~+120℃

Filter Media: Glass Fiber

Filtration Accuracy: 3~30μm

Pressure Indicator Option: 0.35MPa

For Visual and Electrical Indicator Use

By-pass Valve Cracking Pressure: 0.4MPa

Bowl Housing: Aluminum Alloy

Sealing Material: NBR

Fluid Compatibility: Suitable for mineral oil, synthetic oil

Please contact our sales staff if there is any additional media you need.

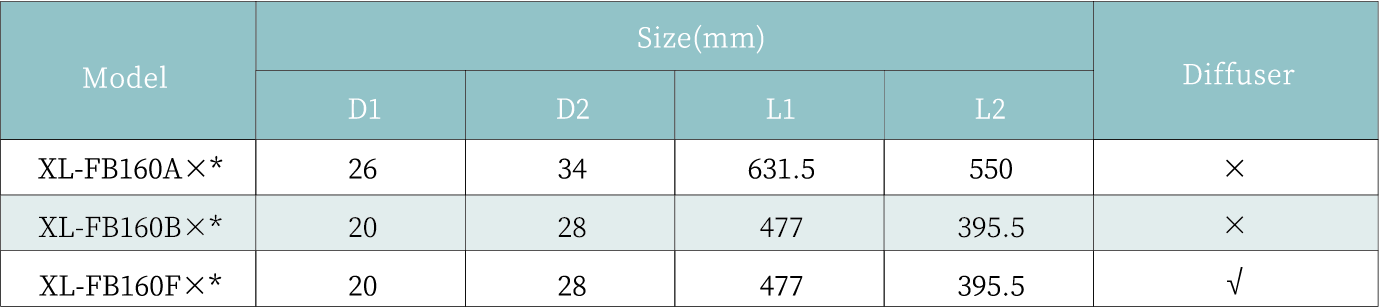

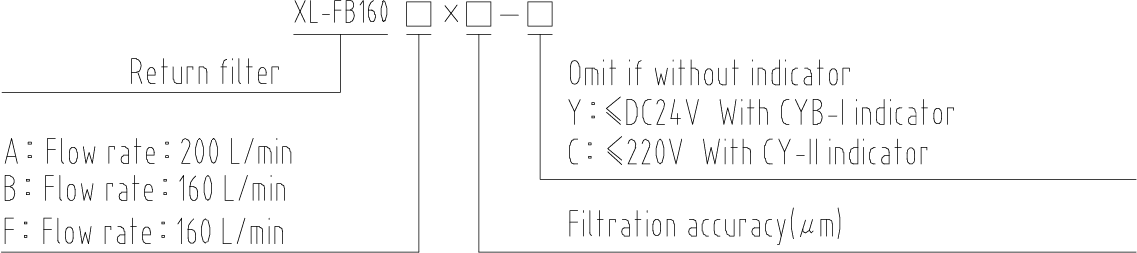

Model Code

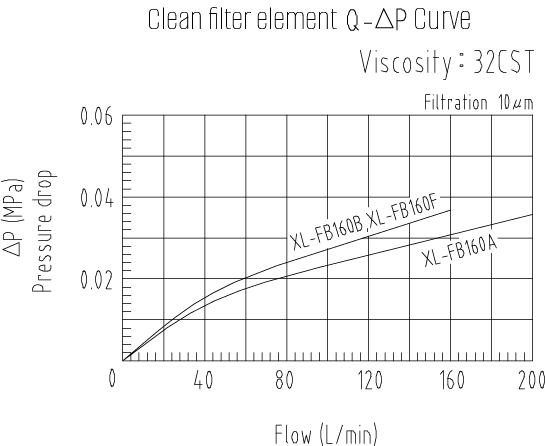

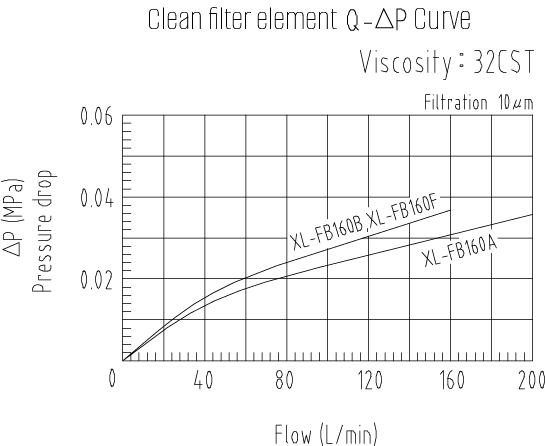

Element Pressure Drop against Flow Curves

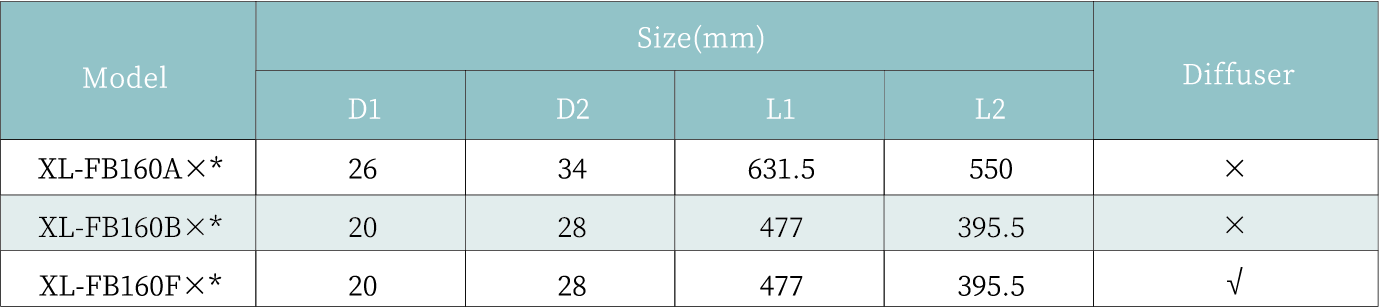

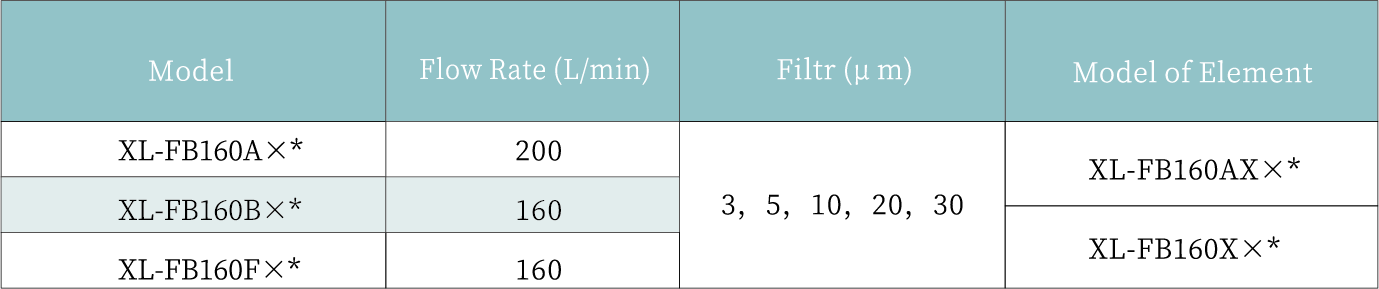

Technical Parameter

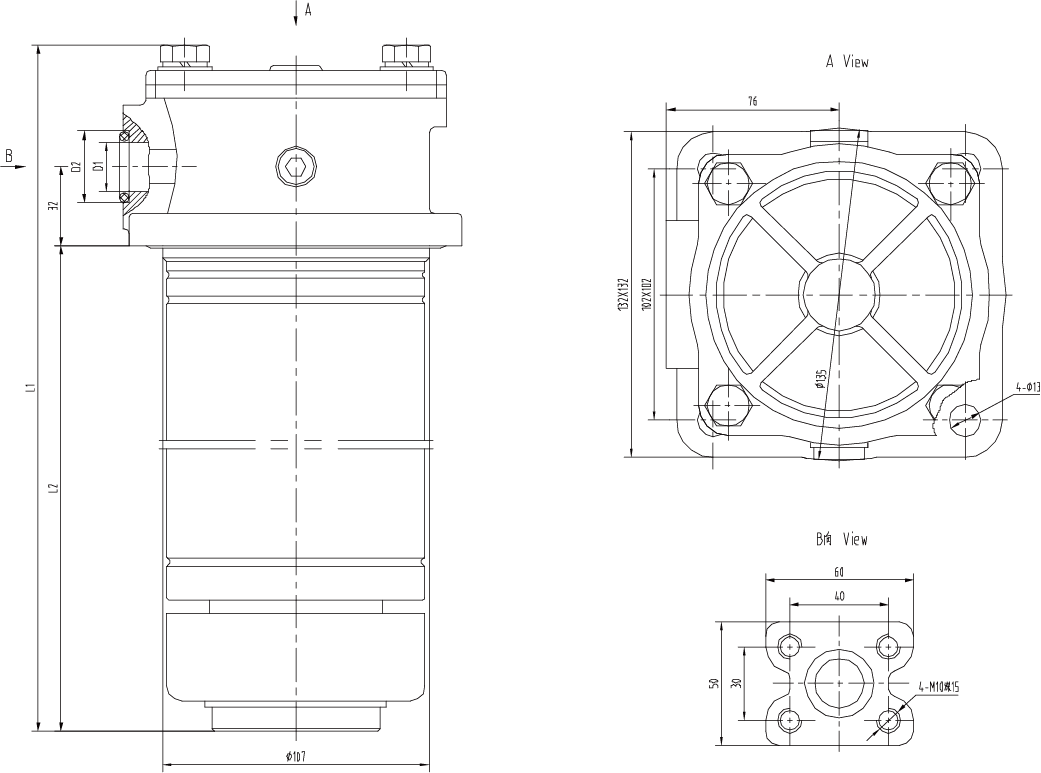

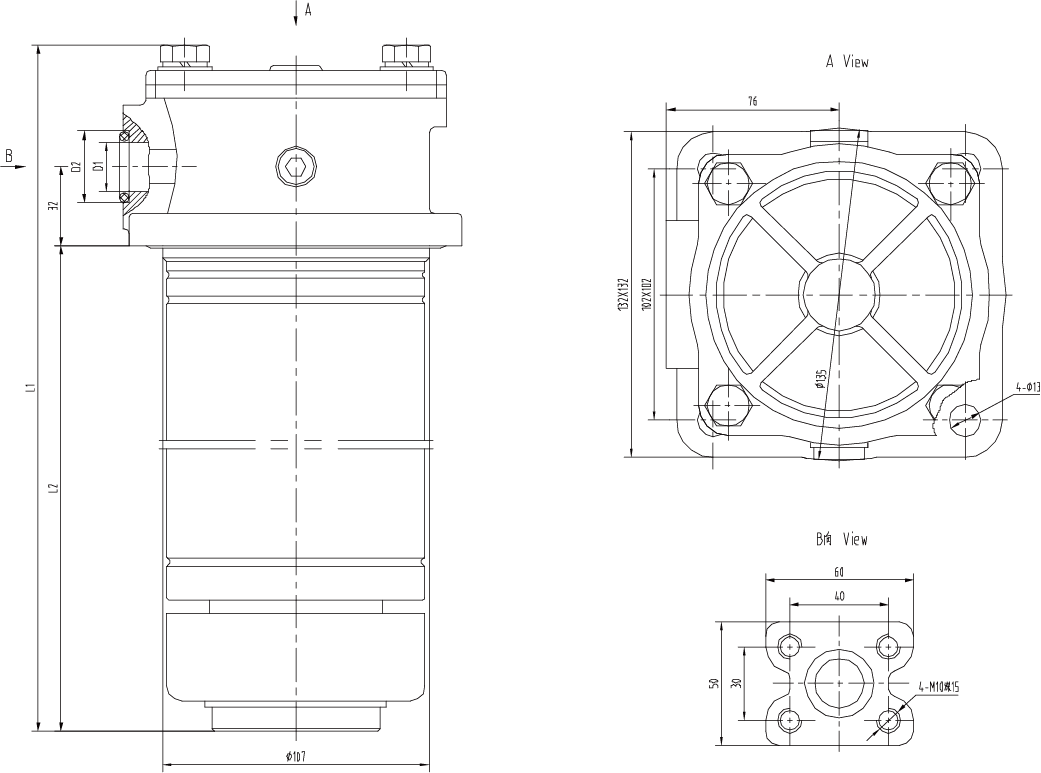

Mounting Diemension